What, Why, How

I augmented a garment, in this case a dress, with conductive fibers, designed to heat up and turn thermochromic ink (i.e., Hypercolor), from one color to another. The participant would wear the garment, which would dynamically reflect the current number of people who have come by his/her site for that day. By comparing the previous day's numbers against the daily average, one of two icons are 'turned on' via resistive heating, displaying whether or not there has been a dip or rise in daily visitors.

I wrote a java app that communicates with the dress via bluetooth, which pings a php script responsible for reporting the server's number of hits for the week. The user is required to fire up the app on their cellphone, which initiates the datascraping and transmission process.

Here's a diagram that illustrates this interaction:

Hardware/Software

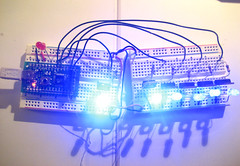

The hardware in this project is minimal, with most of the work being done in the software.

Here's a list of parts I'm using:

Arduino

BlueSMiRF

2 Darlington transistors (TIP120)

2 - 1k resistors

3 - 9v Batteries

Conductive thread (which takes the place of wires in my circuit)

Thermochromic ink, mixed with regular screening ink.

And here's a list of what I coded in:

PHP for datascraping

Arduino code for chip

J2ME

Circuit Schematic

Each conductive thread has its own power supply, since I am shorting out a battery in order to get enough heat generated to cause color change in the ink. I'm PWMing transistors, which switch the threads on and off. All of the components in the circuit share a common ground, but for the threads running through the thermochromic ink icons, when and if they receive power is controlled by turning the gate that goes to ground, on and off, in the transistor.

Set-backs

There are many issues that came up during this project, that are discused in more detail in the blog entries below this one, but these are some of the major ones:

- Conductive thread is fairly tricky to work with. Voltage is lost very rapidly down a length of thread, and you have to be sure to insulate everything in your circuit, since the fiber acts as a live, unshielded wire, when it has power running through it! Fabric glue, hot glue, and/or interfacing (which has glue on its backside; you adhere it to your garment by ironing it on) all work well for insulating soft circuits.

- Related to the voltage/current dropping along the conductive threads, it was hard to get the ink to change color enough without using a 9V battery, and even then, it wasn't as noticeable as it could have been.

- The ink doesn't change as much on my dress, and I had it changing on a test swatch of fabric earlier. This was due to not only a lack of current, from power being lost down the thread; it was also from a poor mixture of screen inks. You have to experiment, in order to get the right combination of thermo/regular screen ink. Also, it works better to have the ink painted over the thread that is responsible for heating it up, versus just having it stitched on top.

- Power supply is the biggest bear of a problem, considering this is a wearable. Having three 9V batteries tethered close to your body isn't the most ideal set up.

- Related to power supply, using Bluetooth is VERY power consuming. The batteries were being drained fairly quickly because of it. I don't have an exact battery lifetime expectancy figured out yet, because I haven't had the garment running long enough to completely drain a battery out. I will post later what I find, in terms of exact numbers.

What worked well

- Darlington transistors to switch the threads on and off works wonderfully, and most importantly, simply. I started out using MOSFET chips, but found that the transistors did the job well enough.

- Using the phone as a constant access point for the internet was a lot less complicated than I had anticipated. It's a great, convenient way to send and retrieve data between the net and your device.

- Using fabric interfacing to create battery holders was a fast, strong, and easy way to get the job done. You just have to iron them in place, leaving a pocket to slip the battery into.