I also tested sending current down different conductive threads to affect color change in my thermochromic ink, designed to change color at body temp or above. Threads with higher resistance work best, and I have placed an order for Bekaert VN 14 1/90 thread. It has a resistivity of 70 ohms/meter. Also, the thread is quite thin, almost like regular thread, so I may be able to use a sewing machine (I hope so!)

observe:

before power!

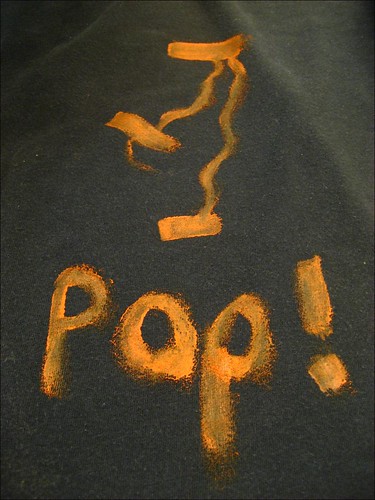

after power!

How to safely power this is still a problem, however. The easiest, yet obviously least desirable way, is to short a battery out while heating the thread. This naturally occurs when you respectively place either ends of the thread you are trying to heat, on the power and negative terminals of a battery; there are no components along the circuit using up all the voltage. It's basically a direct connection from the negative end of the battery terminal to the positive. Sparks fly and smoke wafts... something which is a bit disconcerting.